Expo

view channel

view channel

view channel

view channel

view channel

Medical Imaging

AICritical Care

Patient CareHealth ITPoint of CareBusiness

Events

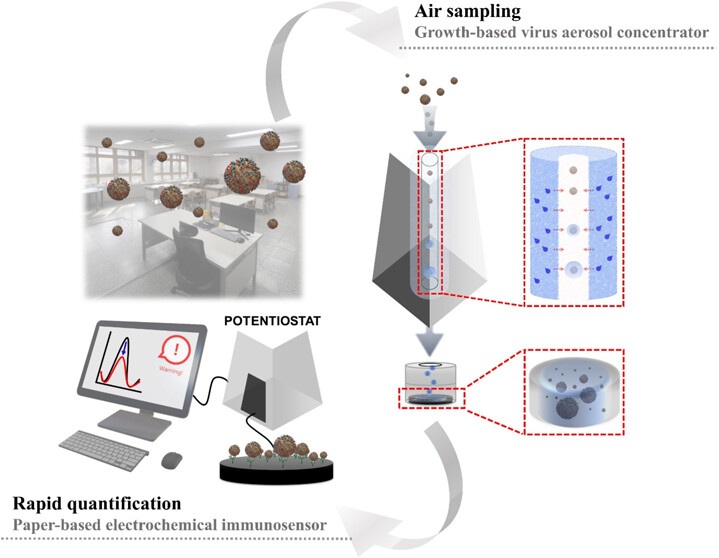

- Groundbreaking Technology Rapidly Detects Airborne Influenza Viruses

- Flexible Semi-Autonomous Robot Could Deliver Medicine Inside Body

- Handheld Device Could Transform Heart Disease Screening

- Gene Discovery Could Help Grow New Heart Arteries

- Neurorestorative Treatment Strategies Hold Promise for Most Severe Forms of Epilepsy

- New Transcatheter Valve Found Safe and Effective for Treating Aortic Regurgitation

- Minimally Invasive Valve Repair Reduces Hospitalizations in Severe Tricuspid Regurgitation Patients

- Tiny Robotic Tools Powered by Magnetic Fields to Enable Minimally Invasive Brain Surgery

- Magnetic Tweezers Make Robotic Surgery Safer and More Precise

- AI-Powered Surgical Planning Tool Improves Pre-Op Planning

- First-Of-Its-Kind Portable Germicidal Light Technology Disinfects High-Touch Clinical Surfaces in Seconds

- Surgical Capacity Optimization Solution Helps Hospitals Boost OR Utilization

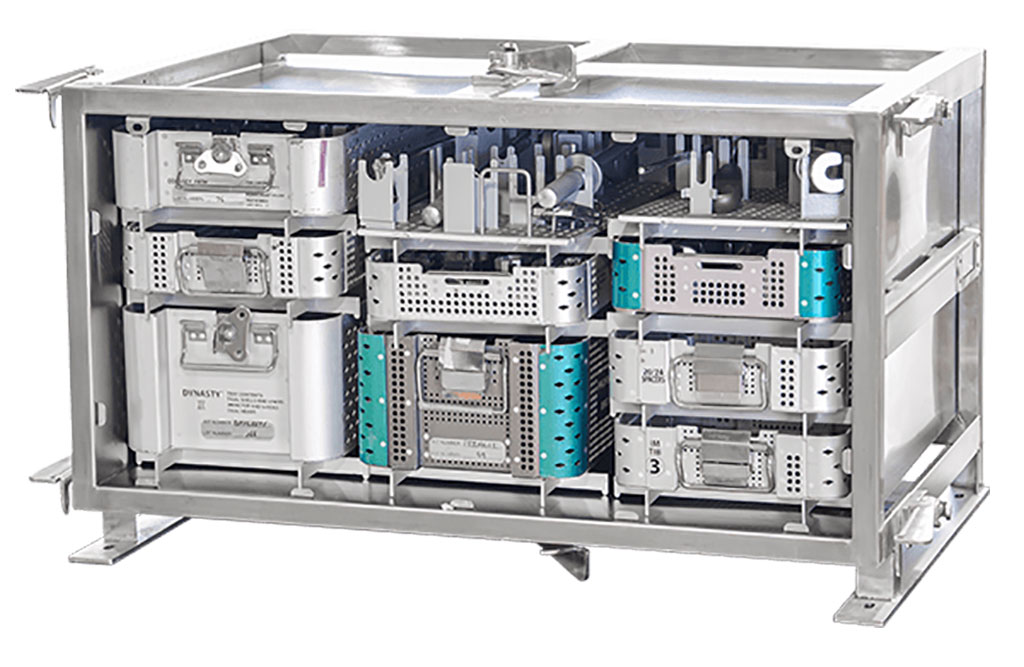

- Game-Changing Innovation in Surgical Instrument Sterilization Significantly Improves OR Throughput

- Next Gen ICU Bed to Help Address Complex Critical Care Needs

- Groundbreaking AI-Powered UV-C Disinfection Technology Redefines Infection Control Landscape

- Becton Dickinson to Spin Out Biosciences and Diagnostic Solutions Business

- Boston Scientific Acquires Medical Device Company SoniVie

- 2026 World Hospital Congress to be Held in Seoul

- Teleflex to Acquire BIOTRONIK’s Vascular Intervention Business

- Philips and Mass General Brigham Collaborate on Improving Patient Care with Live AI-Powered Insights

- Smartwatches Could Detect Congestive Heart Failure

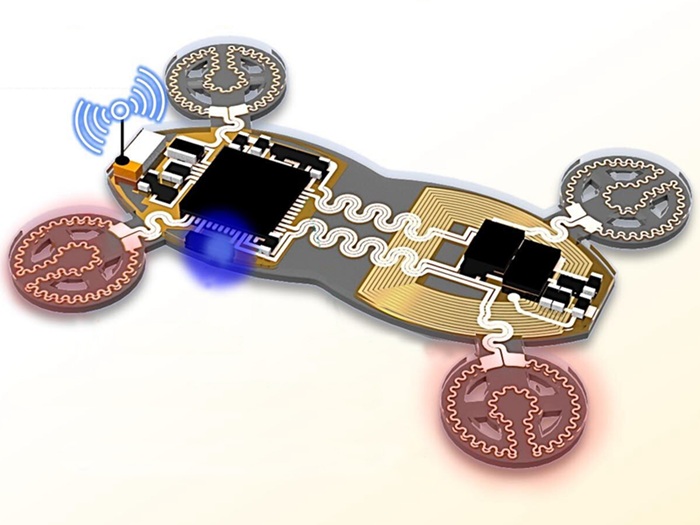

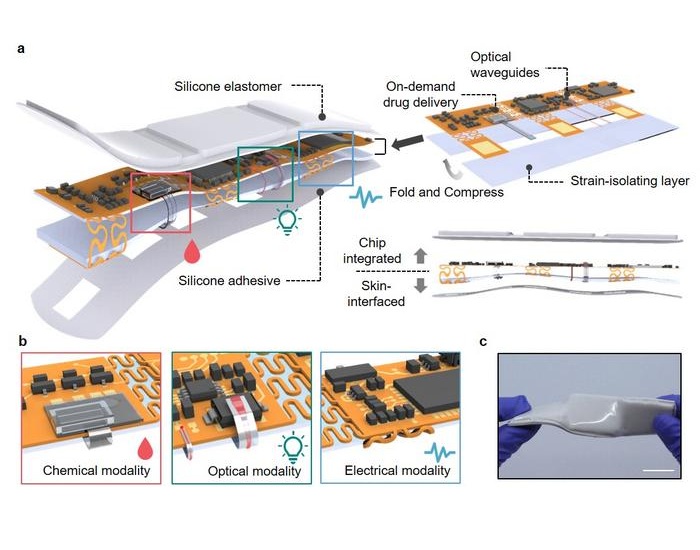

- Versatile Smart Patch Combines Health Monitoring and Drug Delivery

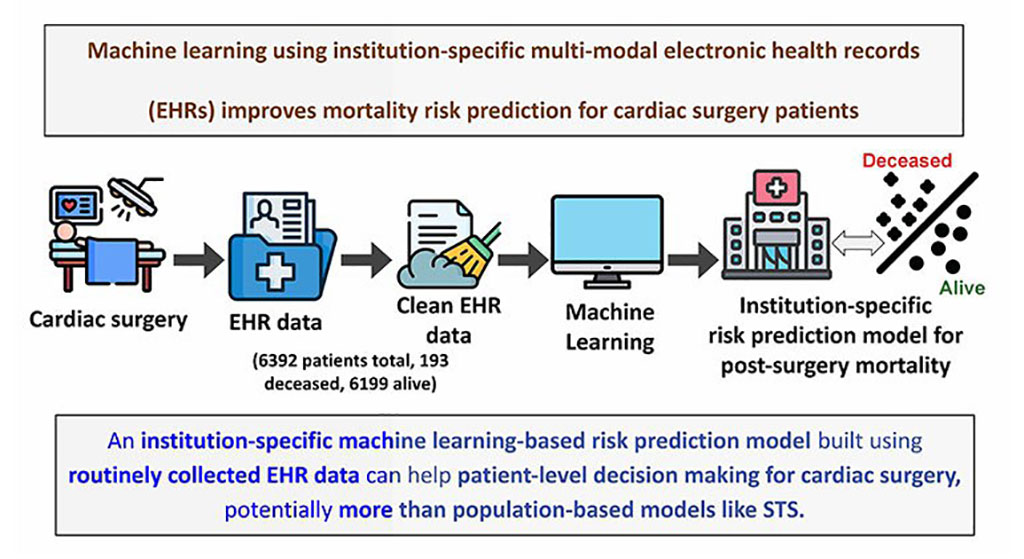

- Machine Learning Model Improves Mortality Risk Prediction for Cardiac Surgery Patients

- Strategic Collaboration to Develop and Integrate Generative AI into Healthcare

- AI-Enabled Operating Rooms Solution Helps Hospitals Maximize Utilization and Unlock Capacity

Expo

Expo

- Groundbreaking Technology Rapidly Detects Airborne Influenza Viruses

- Flexible Semi-Autonomous Robot Could Deliver Medicine Inside Body

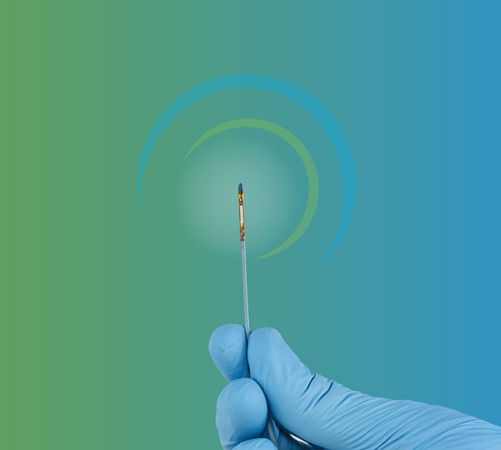

- Handheld Device Could Transform Heart Disease Screening

- Gene Discovery Could Help Grow New Heart Arteries

- Neurorestorative Treatment Strategies Hold Promise for Most Severe Forms of Epilepsy

- New Transcatheter Valve Found Safe and Effective for Treating Aortic Regurgitation

- Minimally Invasive Valve Repair Reduces Hospitalizations in Severe Tricuspid Regurgitation Patients

- Tiny Robotic Tools Powered by Magnetic Fields to Enable Minimally Invasive Brain Surgery

- Magnetic Tweezers Make Robotic Surgery Safer and More Precise

- AI-Powered Surgical Planning Tool Improves Pre-Op Planning

- First-Of-Its-Kind Portable Germicidal Light Technology Disinfects High-Touch Clinical Surfaces in Seconds

- Surgical Capacity Optimization Solution Helps Hospitals Boost OR Utilization

- Game-Changing Innovation in Surgical Instrument Sterilization Significantly Improves OR Throughput

- Next Gen ICU Bed to Help Address Complex Critical Care Needs

- Groundbreaking AI-Powered UV-C Disinfection Technology Redefines Infection Control Landscape

- Becton Dickinson to Spin Out Biosciences and Diagnostic Solutions Business

- Boston Scientific Acquires Medical Device Company SoniVie

- 2026 World Hospital Congress to be Held in Seoul

- Teleflex to Acquire BIOTRONIK’s Vascular Intervention Business

- Philips and Mass General Brigham Collaborate on Improving Patient Care with Live AI-Powered Insights

- Smartwatches Could Detect Congestive Heart Failure

- Versatile Smart Patch Combines Health Monitoring and Drug Delivery

- Machine Learning Model Improves Mortality Risk Prediction for Cardiac Surgery Patients

- Strategic Collaboration to Develop and Integrate Generative AI into Healthcare

- AI-Enabled Operating Rooms Solution Helps Hospitals Maximize Utilization and Unlock Capacity