Expo

view channel

view channel

view channel

view channel

Medical Imaging

AICritical Care

Patient CareHealth ITPoint of CareBusiness

Events

Webinars

- Brain-Based Biomarker Could Predict Alzheimer’s Disease Progression

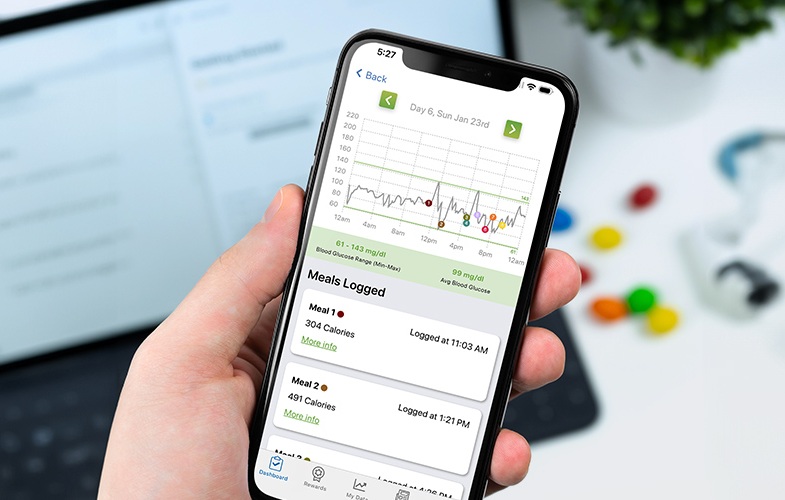

- AI Model Detects Hidden Diabetes Risk by Reading Glucose Spikes

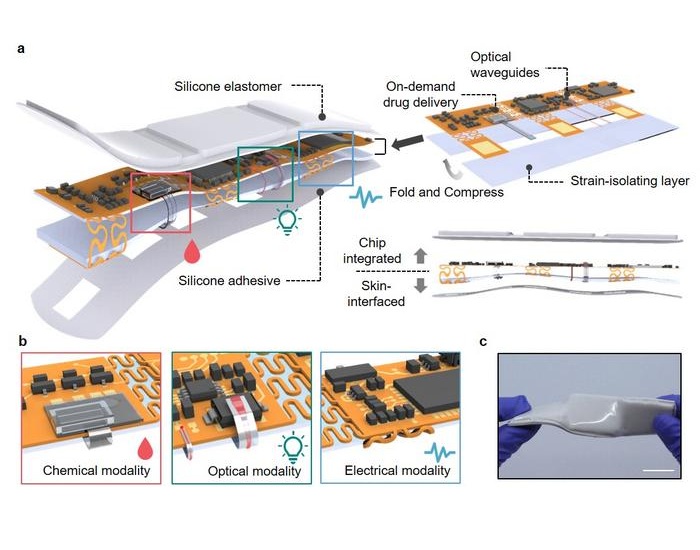

- Wearable Wound Monitoring Device to Improve Chronic Infection Care

- World's First Wearable-Powered System Predicts Acute Inflammation With 90% Sensitivity

- Swallowable Biosensor Pill Tracks Inflammatory Bowel Disease

- AI Cuts Diagnostic Delays in Prostate Cancer

- Surgical Micro-Robot Sees and Corrects Movements from Within

- 'Google Maps' for Surgeons to Help Perform Complex Robot-Assisted Esophagectomy

- New Technique for Measuring Brain Blood Flow During Surgery Can Prevent Strokes

- Computational Model Accurately Simulates Shunt Performance to Prevent Repeat Surgeries

- VR Training Tool Combats Contamination of Portable Medical Equipment

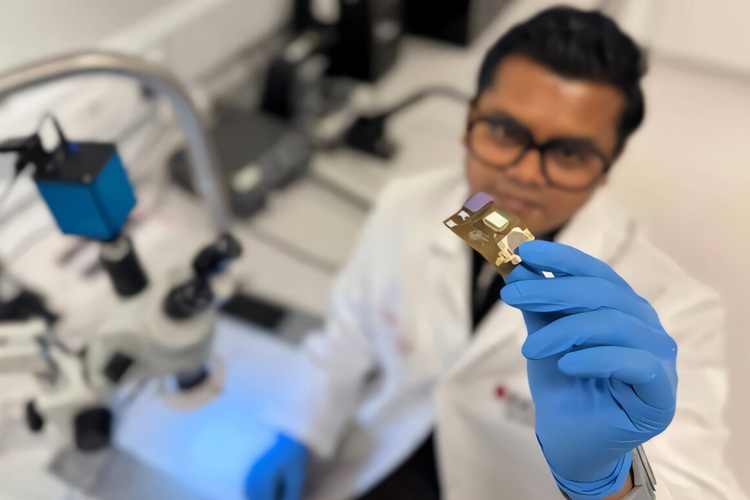

- Portable Biosensor Platform to Reduce Hospital-Acquired Infections

- First-Of-Its-Kind Portable Germicidal Light Technology Disinfects High-Touch Clinical Surfaces in Seconds

- Surgical Capacity Optimization Solution Helps Hospitals Boost OR Utilization

- Game-Changing Innovation in Surgical Instrument Sterilization Significantly Improves OR Throughput

- Medtronic Partners with Corsano to Expand Acute Care & Monitoring Portfolio in Europe

- Expanded Collaboration to Transform OR Technology Through AI and Automation

- Becton Dickinson to Spin Out Biosciences and Diagnostic Solutions Business

- Boston Scientific Acquires Medical Device Company SoniVie

- 2026 World Hospital Congress to be Held in Seoul

Expo

Expo

- Brain-Based Biomarker Could Predict Alzheimer’s Disease Progression

- AI Model Detects Hidden Diabetes Risk by Reading Glucose Spikes

- Wearable Wound Monitoring Device to Improve Chronic Infection Care

- World's First Wearable-Powered System Predicts Acute Inflammation With 90% Sensitivity

- Swallowable Biosensor Pill Tracks Inflammatory Bowel Disease

- AI Cuts Diagnostic Delays in Prostate Cancer

- Surgical Micro-Robot Sees and Corrects Movements from Within

- 'Google Maps' for Surgeons to Help Perform Complex Robot-Assisted Esophagectomy

- New Technique for Measuring Brain Blood Flow During Surgery Can Prevent Strokes

- Computational Model Accurately Simulates Shunt Performance to Prevent Repeat Surgeries

- VR Training Tool Combats Contamination of Portable Medical Equipment

- Portable Biosensor Platform to Reduce Hospital-Acquired Infections

- First-Of-Its-Kind Portable Germicidal Light Technology Disinfects High-Touch Clinical Surfaces in Seconds

- Surgical Capacity Optimization Solution Helps Hospitals Boost OR Utilization

- Game-Changing Innovation in Surgical Instrument Sterilization Significantly Improves OR Throughput

- Medtronic Partners with Corsano to Expand Acute Care & Monitoring Portfolio in Europe

- Expanded Collaboration to Transform OR Technology Through AI and Automation

- Becton Dickinson to Spin Out Biosciences and Diagnostic Solutions Business

- Boston Scientific Acquires Medical Device Company SoniVie

- 2026 World Hospital Congress to be Held in Seoul